CO2 Data Management

Make your carbon capture measurable, documentable and value-adding

CCUS changes the flue gas – but not your compliance

Let ReportLoq ensure you remain compliant with your environmental terms after carbon capture.

Biogen & fossil CO2

Fragmentation via C14 methodFragmented mass emissions accounting

Let ReportLoq split your measured kilos into fossil and biogenic share

Comply with emission limits after CO2 capture

Document continued IED compliance - even when the flue gas changesIED compliance with CC systems

Let a simple correction of flue gas emissions ensure compliance with limit values

CO2 mass emissions

Convert to kilograms under R-EOTConvert concentrations to kilograms

Calculation of mass emissions and handling of replacement values is automated in the DAHS system

Credible reporting in changing times

Carbon capture changes the flue gas – and many people only realize this when the emission values suddenly no longer comply with environmental regulations.

ReportLoq helps you overcome key data challenges after CC installation:

Including correct comparison with IED limits, division into biogenic and fossil CO2 and accurate calculation of mass emissions.

It’s a single solution so you can continue operations, documentation and regulatory reporting without manual spreadsheets and expensive system changes.

CO2 – from measurement to decision

CO2 is at the heart of the green transition. As the EU’s climate targets tighten, accurate and verifiable CO2 measurements become a crucial basis for environmental reporting, carbon offsetting and business decisions.

For industry, this means that the quality of data is just as important as the quantity of data.

When the flue gas changes – whether due to process optimization, fuel switching or installation of CO2 capture – the calculation basis also changes.

Without proper reference, validation and traceability, even small measurement deviations can have major consequences for reporting and billing.

That’s why CO2 data management has become a strategic discipline.

It’s not just about collecting measurements, but ensuring that each data point is quality assured, calculated and stored in a way that can be documented – even years later.

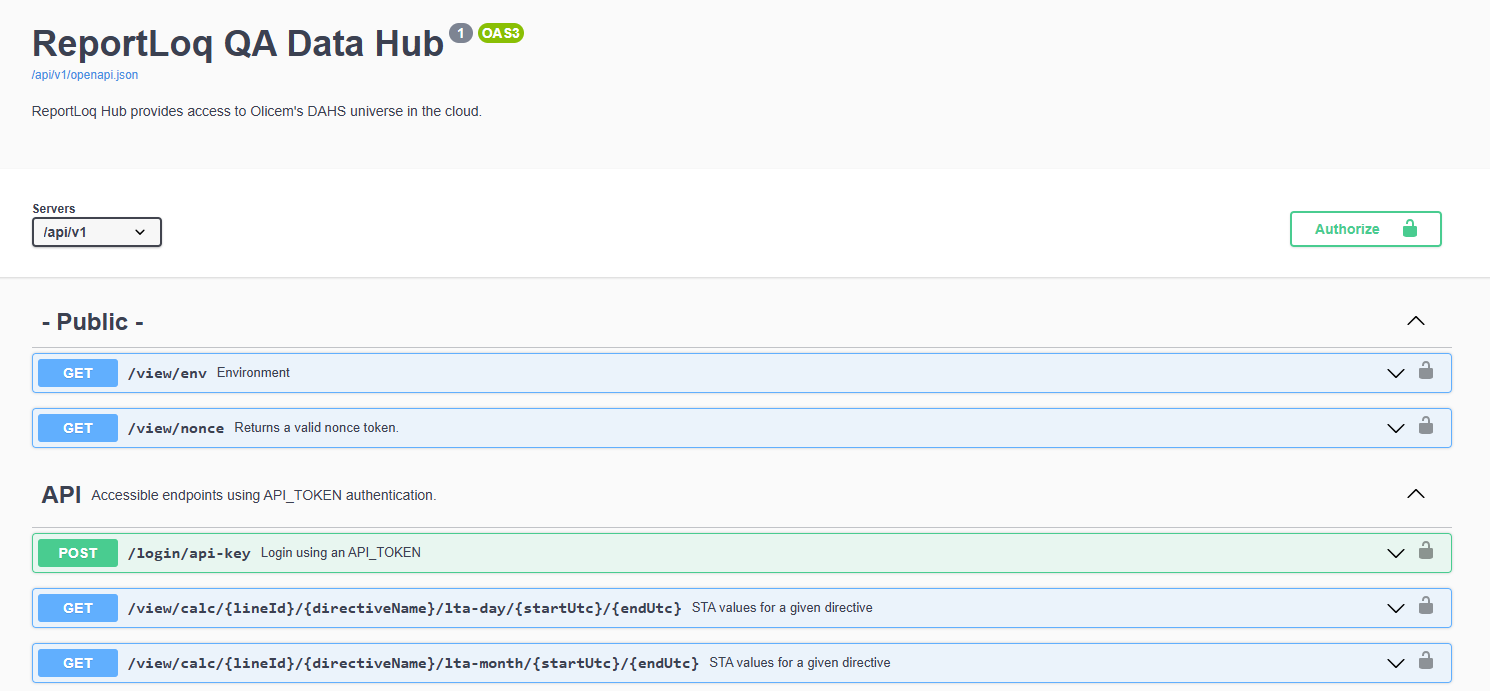

This is where ReportLoq DAHS and Olicem’s API solution ReportLoq QA Data Hub come into play.

Together they form a complete solution where all emission and CO2 data is quality assured, calculated and stored according to EN 17255.

The hub connects the local measurement equipment with the company’s IT infrastructure and makes data ready for reporting, ETS reporting or CO2 capture projects – always with full traceability and data integrity.

In a nutshell: A DAHS system that makes CO2 data credible, comparable and usable – from sensor to report.

ReportLoq DAHS

With ReportLoq DAHS as a stand-alone system, you get a certified system for collecting measurements and calculations according to EN 17255 and IED standards.

Among the system’s many features you’ll find support for QAL2 and QAL3 with the option for automatic QAL3. This ensures accurate emissions data for further reporting.

The system calculates mass emissions based on measured flow and operating time and takes NOC and OTNOC into account to ensure correct reporting according to legislation.

When the DAHS system is extended with the CO2 module, it will support CO2 fragmentation, conversion of emissions measured after CC to the state before CC with support for full or partial bypass with totals in easy-to-read reports.

ReportLoq Cloud

Ultimately, you can choose to connect the DAHS solution to ReportLoq Cloud, which exposes your data via www.reportloq.com.

Here you get among other things:

- Easy online access

- Email support so reports can be delivered directly to your mailboxes

- An unlimited number of users

- Secure Office365 user management

- … AND the option to add the ReportLoq QA Data Hub API solution, which gives your IT department direct access to the platform’s quality-assured data via Open API 3.0 and a user-friendly Swagger interface.

More information can be found in the Features overview

ReportLoq QA Data Hub

The hub is the central entrance to the company’s emissions and CO2 data, where all measurements are quality assured (QA). It acts as a filter to ensure that only validated and traceable data is passed on for decision-making, reporting and integration into the company’s own IT systems.

A natural part of the company’s infrastructure

Customers can connect their IT systems to the Hub and retrieve the quality-assured data directly. This makes CO2 Data Management not an isolated island, but a natural element in the overall digital infrastructure – in line with financial systems, production systems and energy optimization tools.

For cloud-based DAHS customers

It is important to emphasize that QA Data Hub is a cloud-based solution. Therefore, it can only be used by customers using Olicem’s DAHS in the cloud version. For these customers, the Hub provides unparalleled flexibility.

For CO2, the integration with ReportLoq QA Data Hub means you don’t risk stumbling into difficult CO2 calculations. Instead, let the values we have already quality assured become part of your infrastructure. Then you can concentrate on your operations and the CO2 you have captured and the release that is still there. If you haven’t captured CO2 yet, the Hub is still just as relevant, as the data can also be used for further reporting and processing – and so you always act on valid data.

Biogen & fossil CO2

Automatic fragmentation of CO2 streams

As ETS requirements are tightened, companies must be able to document how much of their emissions come from biogenic material and how much is fossil-based.

At many plants, this breakdown has so far required manual calculations in spreadsheets – a process that is both time-consuming and vulnerable to errors.

With the addition of the CO2 module, the calculation is performed directly in ReportLoq DAHS.

The system uses reference values, fuel types and analyses from process data to automatically determine the proportion of biogenic and fossil CO2 in the flue gas.

The result is saved as traceable data that can be used directly in ETS reporting and climate accounts.

Comply with emission limits after Carbon Capture

IED compliance – even when the flue gas changes

When a capture plant is connected, the composition of the flue gas changes.

This means that emissions measured after the CC plant can no longer be directly compared to the IED limits that apply to the plant.

This is where the biggest cause of error in many CC projects occurs: you think you are still reporting correctly – but the reference ratio has changed.

Olicem’s method maintains comparability by using the pre-capture oxygen measurement as a reference.

The emissions after CC are then automatically corrected with a calculated factor so that the values can again be compared with the IED limits.

The solution is built into ReportLoq and documented in the reporting so that compliance can be maintained without extra measurement points or manual corrections.

CO2 mass emissions

From concentration to mass – by industry standard

Most environmental permits and quota accounts require CO2 emissions to be reported as mass emissions in tons or kilograms.

For the calculation to be approved, the conversion from concentration (ppm or %) to mass must follow recognized standards and be performed with quality assured data.

ReportLoq performs this calculation automatically from continuous measurements of concentration, temperature, pressure and flow – and uses the standardized formulas used in the industry B-EOT methodology.

Each calculation is stored with full traceability and uncertainty indication, so mass emissions can be used directly in environmental reporting, ETS reporting or financial settlements.