ReportLoq is an environmental reporting system that differs from similar systems in many ways. Our vision is to create a user-friendly, high-quality system that is easy to use. ReportLoq operates independently of existing control systems and can be integrated with all types of measuring equipment. A significant difference from other similar systems is that ReportLoq is a program and not a SCADA system. The graphical user interfaces in ReportLoq therefore do not have to be set up for each system, but are instead automatically generated from the setup file that Olicem delivers to your system along with the license key. This approach minimizes sources of error and ensures the same high quality of software for all types of systems. At the same time, this means that ReportLoq does not take long to set up. Below is a selection of the features found in ReportLoq. Together they form the basic functionality of the user interface of the DAHS system. The actual functions depend on the selected ReportLoq product, and can be seen in the function matrix. The screenshots originate from ReportLoq Soft and ReportLoq+ , and will vary to a lesser extent in ReportLoq+ Cloud and ReportLoq Pure+ Cloud. These can instead be viewed via the demo access at www.reportloq.com.

Standardfunktioner

- Real-time data visualization

- Combined overview

- QAL (Quality Assurance Levels)

- Trend

- Reports

- Historical exceedances

- Historical alarms and events

- Export to CSV

- OTNOC

- Configurable dashboard

Optional features

ReportLoq’s optional features are an extension of the standard features and must be ordered separately.

Real-time data visualization.

According to EN 17255-1:2019, data must be reported to environmental authorities as normalized values. This means both QAL correction and normalization of measured values before they can be calculated to average values and deducted confidence interval. The set of rules means that the measured value is often very different from the average value. The CEMS page therefore provides an overview that explains how the measured raw value is corrected step by step. The overview helps the operator to keep the emissions below any limit values, and provides warnings if the system is in the risk zone for exceeding the emission limit. The local ReportLoq server has, as shown in the screenshot, a list of alarms and exceedances so that the operator can easily comment on the events directly. The comments can be used directly on the exceedance reports to the environmental authorities.

Combined overview

In plants with multiple incineration lines, it can be advantageous to gather the overview from several lines on fewer screens. This is exactly what the combined overview allows for. Only the raw and quality-assured values are shown here. The fewer columns, in turn, allow you to combine multiple incineration lines on the same screen. Note that it is possible to create multiple screens, each with their own combination of incineration lines. The alarm list on the right side of the screen can be turned on or off, depending on your needs and space.

QAL (Quality Assurance Levels)

According to the standard for quality assurance of automatic metering systems, meters used for environmental reporting must be quality assured according to QAL regulations. ReportLoq follows EN 14181:2014 by allowing QAL2 and QAL3 and AST to be entered.

QAL2 – Parallel measurement with calibration function

After the QAL2 test has been performed by the accredited measurement institute, the calibration function must be applied to the measured values in the environmental reporting system. The values are entered in ReportLoq with slope and cut as stated in the report and work from the next day. It is also possible to enter the calibration function from QAL2 in ReportLoq. This automatically checks whether the measurements are within the calibration interval. At more than 5% or 40% overrun, overruns are automatically created in the system.

QAL3 – Continuous quality control

Meters without automatic calibration function often need to be corrected manually using calibration gases. In ReportLoq it is possible to create the calibration gas and the quality control will then be quick to perform. At each calibration, the created calibration gas is applied and the measured value is entered in ReportLoq. Hereby it is calculated via the CUSUM method whether the meter is within the valid measuring range. In case of minor overruns or underruns, ReportLoq recommends adjusting the meter value. Adjustments will then take effect from the next day. In case of heavy operation on the meter, the operator is asked to call a service technician to the meter.

AST – Checking calibration function and measurement performance

The annual quality control of the meter is mentioned in EN 14181, which describes how to check the calibration function of the QAL2. One of the products of AST is a new calibration range that must be used by the plant owner. When creating AST in ReportLoq, the check for 5 weeks of 5% exceedances is reset in ReportLoq.

Trend

In ReportLoq, you can trend your emissions in the multi-axis trend tool. Here you can, among other things

- See raw logged values that reflect the meter’s values over time

- Compare QAL2, QAL3, corrected, or quality assured FLD values with the confidence interval subtracted

- Easily visualize pre-calculated STA or LTA values (hour, day or month) with mass emission calculations (kilograms).

The many options provide the ultimate flexibility when working with your measurements. Now it is e.g. no longer difficult to see what a correction of water, oxygen, pressure or temperature means for your emissions. You can simply choose to see the value both before and after the correction. This makes it easy to understand the effect of the correction on the calculations. The trend function contains explanatory texts for the logged and calculated values, which makes it possible to easily spot errors or calibrations in the measured values. This avoids misinterpreting a measured value or having to compare the graphs with alarm lists and the like. All trending values can be easily exported to comma-separated files if you want to confinue working with it in e.g. Excel.

Reports

The key to a good reporting system is easy-to-understand reports. In ReportLoq, the set of reports is adapted to the individual situation, so that the overview is always the best possible. Many of the reports are available as daily, monthly and annual reports. The selected reports can all be downloaded both as Excel and PDF files depending on what the report is to be used for. The PDF file is a good tool for reporting to authorities. The Excel file is good if you want to continue working with the figures from the report in another tool. Note that ReportLoq always generates reports based on the calculated data in the internal database. This means you never risk ending up with a report that does not match the data stored in the system. Read more about the many reporting options

Historical overruns

All exceedances ReportLoq has detected can be found under “Exceedances”. The feature gives you a quick insight into which exceedances have been in a period, or how often a particular exceedance occurs. All extracts can be exported to PDF, Excel or CSV files. The date function with speed dial makes it easy to see certain periods with quite a few clicks. It is smart and time saving. The feature includes commenting functionality for both operator and manager.

Historical alarms and incidents

Historical alarms and events on the metering equipment, as well as events such as shutdown, startup and shutdown, are available via the “Alarms and events” function. Here, specific alarms can be quickly searched out, to find the frequency of the alarms or events can be sorted by production line. The feature includes commenting functionality that can help identify causes of alarms over time.

Export to CSV

The export function can export data to comma-separated files. There is an option to export

- Logged FLD values without calculations

- Calculated FLD values in calculation steps of your choice. Eg. QAL2 values for use in parallel measurement.

- Calculated STA or LTA values (hour, day, month)

Calculated values can be exported as green or interval values. Green values contain start-up and shut-down periods and are used when calculating the reporting of mass emissions (kilos). The interval values only contain operating periods and can be held up against limit values. All exported values can be exported with validation texts, which provide a quick overview of the state of the values. It is i.a. possible to identify downtime, exceedances, replaced values and much more. Note, however, that each value is only exported with one status based on priority order.

OTNOC (Other Than Normal Operating Conditions)

The OTNOC feature in ReportLoq enables facilities to record and report periods when operations are not normal, such as during startup or shutdown.

The feature is primarily designed for waste incinerators, but can be enabled at other facilities if there is a need to focus on emissions during abnormal operating conditions.

Automatic and manual registration

OTNOC periods are automatically registered when the plant starts or stops, based on signals from the control system.

Periods can also be created manually in the system.

If a facility chooses to use a specific OTNOC signal from the control system, periods can cover extended start-up and shutdown phases.

Editing and customization

Users can edit OTNOC periods in the system user interface, where it is possible to add comments and select relevant components.

Automatically created periods have fixed start and end times, but it is possible to manually create new periods with adjusted times if needed.

Reporting

The reporting of OTNOC data differs from normal reporting as it does not use mean values, but instead shows First Level Data (FLD) directly from the measurements during OTNOC periods.

This provides a detailed view of emissions during the abnormal conditions.

The reports can be generated as Excel or PDF files and can contain large amounts of data.

In Excel format, the report will include both visualized values and a table with FLD data.

Additional reporting options

In addition to the basic OTNOC report, there are several related reports that provide insight into the impact of OTNOC periods:

- Interval report: Shows which periods on a daily or monthly basis have been affected by OTNOC.

- The Start/Stop operating time report: Shows how much time a combustion line has been running during OTNOC, divided into operation inside and outside normal operating hours.

- OTNOC Daily limit value: Some facilities may need special limit values below OTNOC, which the system can handle automatically.

The OTNOC feature thus allows the user to focus on emissions during abnormal operating conditions and ensure accurate reporting to authorities.

Configurable dashboard

The vast majority of screens in ReportLoq are automatically set up when the system is delivered. The configurable dashboard is an exception. Here you can choose exactly which measured components are to be displayed, which calculations you need, which color, font and size you need. The example shows two lines which here are combined on one screen. We have omitted the peripheral measurements and have thus reduced the amount of values so that the numbers can be displayed in larger print. The possibilities are many and depend entirely on what you yourself think and need. It’s possible to create all the configurations you want.

Optional features

Interval report, Graphical

The monthly report Interval, Graphical visualizes VSTA values subtracted from confidence intervals and compares them to the plant’s limit values. In situations where the plant weights its limit values based on different fuels, it can be difficult to see if the emission values have been complied with without at the same time relating to what the limit values are in the same period. The report’s graphical representation of both the validated emission value (VSTA) and the calculated limit value makes it easy and quick to see where the plant has been in relation to the limit value. Plants without weighted limit values can also use the report. Read more

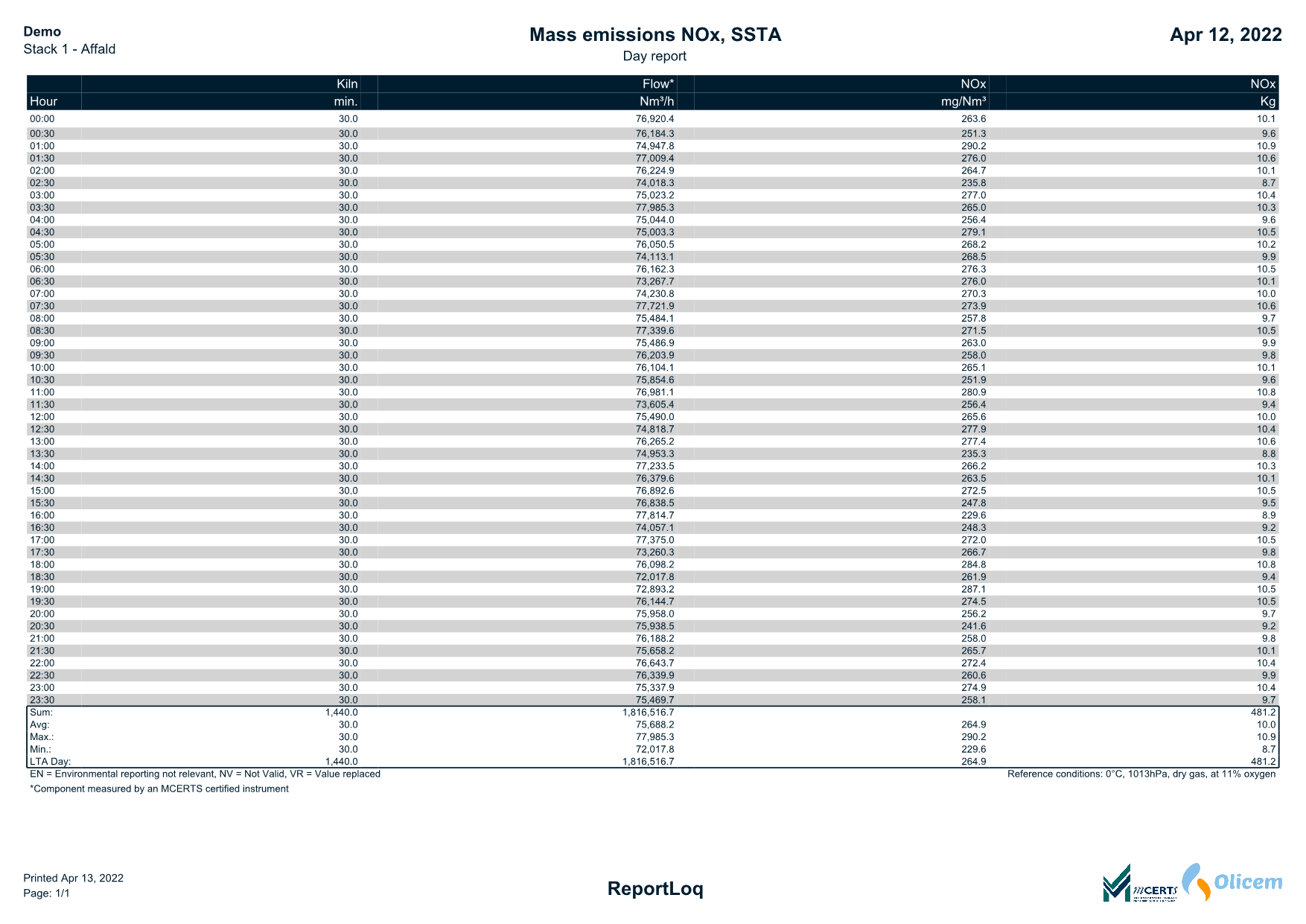

Mass emissions (kg)

Calculating kilograms is necessary if taxes are to be paid on the emitted emissions. ReportLoq automatically calculates kilos* for all setups where, in addition to the emission measurement, flow is measured and where operating signals for the plant are included in the setup. Mass emissions are always calculated under NOC and OTNOC, as described in EN 17255-1:2019, and are calculated for hour, day, month and year. When selecting the function, the report Mass emissions is included, which produces the measured values together with the converted values. This makes reporting to environmental authorities easy and straightforward. * Both conversion from mg/nm3 and VOL% to kilograms is supported.

Real-time monitoring of valid calibration interval

According to EN 14181:2014 (6.5), plants with AMS must comply with the valid calibration interval stated in QAL2/AST. In practice, this means that the plants must make new QAL2 if more than 40% of the SSTA values in one week are outside the range, or if more than 5 weeks of 5% between QAL2 and AST are outside the range. When the plant is in operation, it may therefore be relevant for the plant to compare the SSTA values with the valid calibration interval, so that the operator can predict whether a calibration interval will be exceeded. This function adds visualization of two new elements to the CEMS view. One is an hourly assessment of whether the SSTA value is within the calibration interval. The second is an assessment of how many of the week’s SSTA values are outside the valid calibration range. The assessments can, as shown on the screen, be displayed as two additional columns, and are visible both on CEMS and via the combined overview. A compact display with alarm lights is also included. The solution is smart in cases where you want the calibration interval to be visible without using extra space for the two columns.

Automatic QAL3

Save time and energy in your everyday life with ReportLoq’s automated QAL3 module. The option means that you can configure ReportLoq to keep track of the measured values during analyser verification and that ReportLoq creates new QAL3 records itself. The module can be used for meters that have an automatic periodic verification built-in. For example, meters that are verified at specific times or with specific durations. The module comes with a graphical tool where you can easily view measured values during the measurement verifications. Here you can designate the zero and span cycles, which will enable ReportLoq to find similar zero and span verifications and to calculate drift and instability from the detected values. The following are supported:

- Automatic creation of QAL3 from measurements within tolerance

- Alerting of operators on creation of QAL3 with instability or drift (+ email support in Cloud)

- Users can easily create QAL3 with adjustment from measured values during verification with operation

- Ability to ignore verifications with instability or drift

When ReportLoq saves automatic QAL3 records, they will be saved in the same way as regular QAL3 records and can be viewed in reports and lists. The module uses CUSUM to calculate drift and instability.

CO2 accounting

With the module, data retention is increased to 10 years, replacement values are handled automatically and the breakdown to emitted kilograms in fossil and biogenic share of fuel is calculated automatically.

The module is relevant for:

- Plants reporting CO2 to environmental and tax authorities

- Plants that want to get an overview of measured emissions calculated for fossil and biogenic share

Calculation of CO2 fragments

The module makes it possible to enter fossil/biogenic CO2 fragmentation directly into the reporting system.

The function is intended for plants that take C14 samples and need to enter sample results directly into the reporting system.

Entered fragmentations can be added historically, after which ReportLoq immediately calculates a new fossil/biogenic distribution for the period in question.

Plants that have auxiliary burners can also choose to include them directly in the reporting system, whereby the fossil share of the fuel (e.g. waste) can be calculated directly in the reporting system.

The consumption of the auxiliary burners can be entered as a measured value or entered on a monthly basis.

For waste incineration, the module includes an additional report that calculates the fossil share of the waste.

The report calculates total CO2 emissions for fossil/biogenic share and can automatically deduct support burners.

Calculation of total emissions

The module extends the calculation of mass emissions in ReportLoq with annual automatic replacement of limit values according to Commission Regulation 601/2012.

Commission Regulation 601/2012.

Replacement values for flow and CO2 are calculated based on the year’s valid values plus 2 x measurement uncertainty.

Storage of all logged values and calculated data is increased from 5 to 10 years as described in the regulation.

This ensures compliance with the requirements of Annex IX.